SAMPIBIO® Blender Bags are designed to support efficient sample preparation and microbiological analysis using laboratory homogenizers. Used widely across food production, beverage, pharmaceutical, environmental, and industrial testing, blender bags allow solid and semi-solid samples to be safely blended with diluent prior to microbiological enumeration or further testing. :contentReference[oaicite:0]{index=0}

SAMPIBIO® blender bags are engineered for compatibility with all types of homogenizers, with a wide opening for easy sample insertion and robust construction to reduce the risk of tearing during blending. All bags are supplied sterile, batch traceable, and RNase, DNase, and pyrogen-free to protect sample integrity and ensure reliable results. :contentReference[oaicite:1]{index=1}

Why Use Blender Bags?

Blender bags simplify laboratory homogenisation workflows by allowing samples and diluents to be combined and processed within a single sterile bag. This helps minimise handling steps and reduces the risk of cross-contamination during sample preparation. :contentReference[oaicite:2]{index=2}

- Wide bag opening for fast, aseptic sample loading :contentReference[oaicite:3]{index=3}

- Compatible with all homogenizer types :contentReference[oaicite:4]{index=4}

- Durable construction to reduce tearing during blending :contentReference[oaicite:5]{index=5}

- Supplied sterile with batch number and sterility certificate :contentReference[oaicite:6]{index=6}

When to Use Filtered vs Non-Filtered Blender Bags

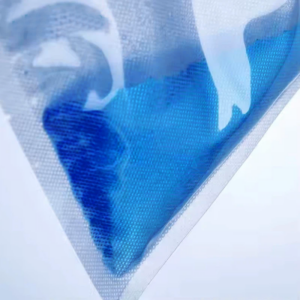

SAMPIBIO® Blender Bags are available in both non-filter and filter formats to suit different sample types and laboratory workflows. Non-filter bags are suitable for general sample blending where a filtrate is not required. Filtered bags enable aliquots to be taken during or after blending without waiting for sedimentation, producing particle-free filtrate that supports cleaner plating and easier reading of Petri dishes. :contentReference[oaicite:7]{index=7}

Filter options include lateral non-woven filters for samples containing fine particles, and full-page filter formats for fast filtration and consistent aliquot collection. Some full-page filter blender bags are available with wire closure systems for airtight and leak-proof sealing during transport. :contentReference[oaicite:8]{index=8}

Blender Bag Options

SAMPIBIO® offers a range of blender bag formats to match different sample consistencies and processing needs:

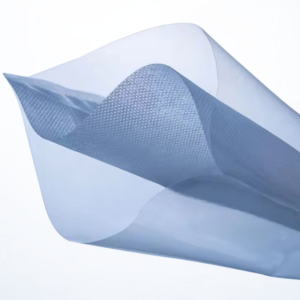

Sterile Plain Blender Bags

Plain blender bags provide a straightforward solution for routine homogenisation and sample preparation. Their transparency allows fast visual inspection of the sample during processing, and they are compatible with all blenders. :contentReference[oaicite:9]{index=9}

Blender Bags with Non-Woven Filters

Non-woven filter blender bags are designed to improve aliquot collection by separating particulate material from the filtrate. Lateral non-woven filter options are particularly suitable for samples containing fine particles, while full-page non-woven filters provide fast, consistent filtration and simplified pipetting. :contentReference[oaicite:10]{index=10}

Blender Bags with Polyethylene Filters

Polyethylene (microperforated) filter blender bags are designed for workflows where rapid filtration and clean aliquots are required, including challenging sample matrices. Full-page polyethylene filter formats are available with or without wire closure systems depending on handling and transport requirements. :contentReference[oaicite:11]{index=11}

Designed for Compliance and Reliability

All SAMPIBIO® blender bags are:

- Pre-sterilised to maintain sample integrity :contentReference[oaicite:12]{index=12}

- Batch traceable with sterility documentation :contentReference[oaicite:13]{index=13}

- RNase, DNase, and pyrogen-free for maximum purity :contentReference[oaicite:14]{index=14}

- Designed for dependable performance in routine and high-throughput laboratory workflows :contentReference[oaicite:15]{index=15}

Download

Download the SAMPIBIO® brochure with FMCG contact details for full product information and ordering support.

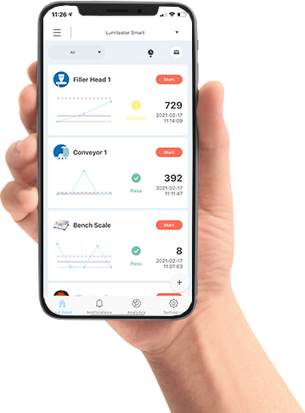

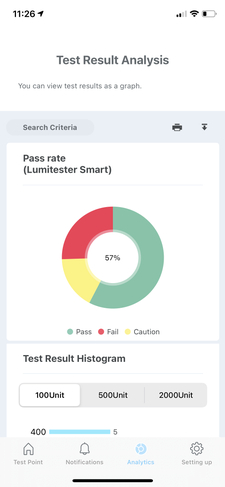

Exportable Data and Reports for Regulatory Compliance

Exportable Data and Reports for Regulatory Compliance

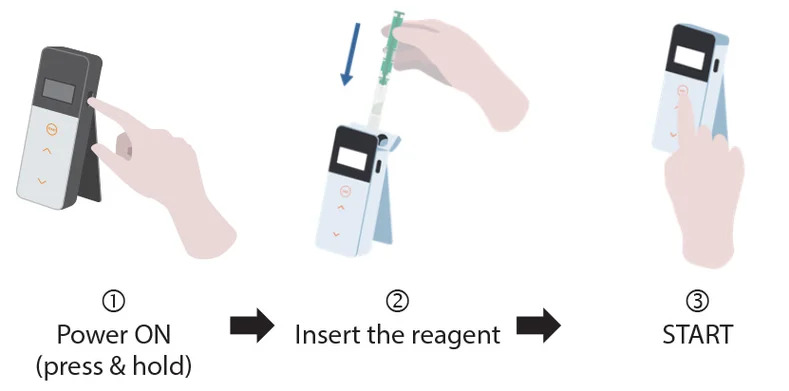

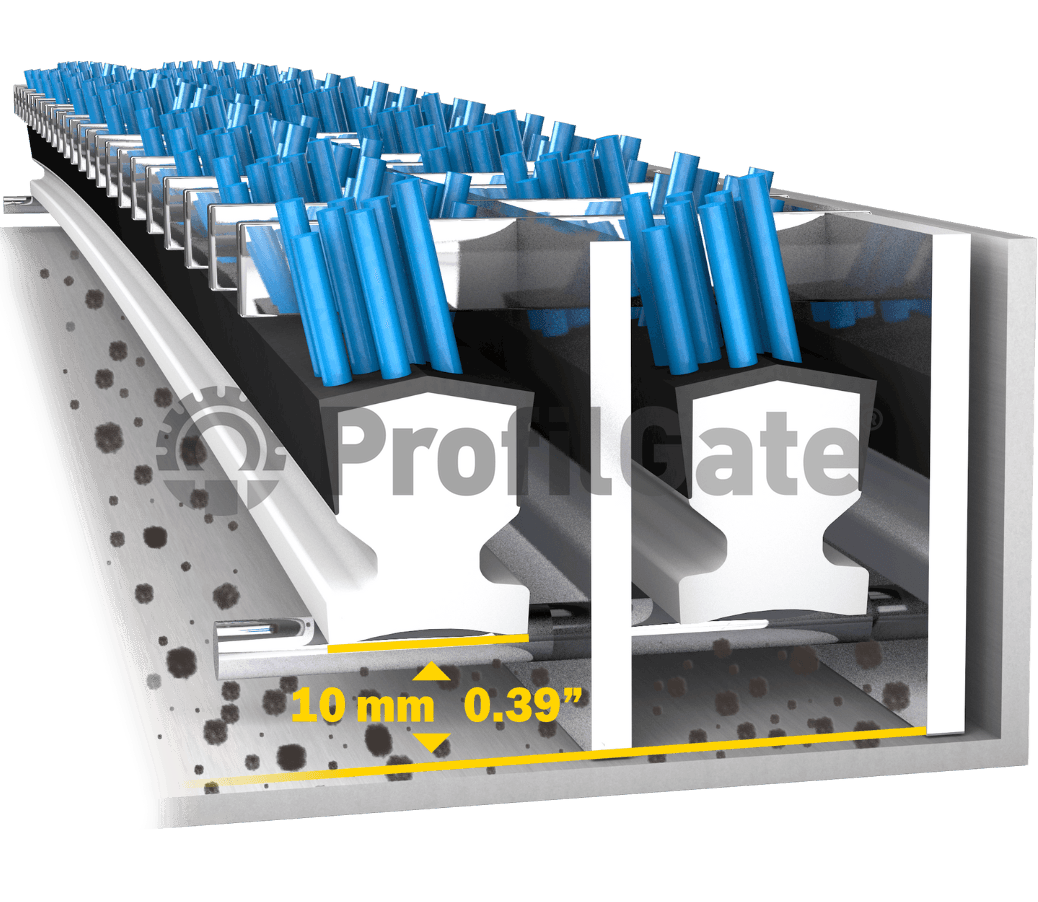

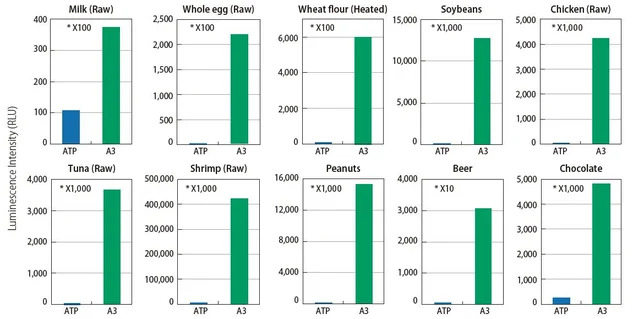

See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t