Setting Practical Pass/Fail Limits in Hygiene Monitoring

In hygiene monitoring, setting meaningful pass/fail limits is critical for ensuring cleaning effectiveness while keeping standards realistic and motivating for staff. Arbitrary thresholds can either be too lenient or too strict, which creats confusion instead of confidence. A data-driven approach allows facilities to tailor limits that truly reflect their cleaning performance.

Case Study: University of Wisconsin–Madison

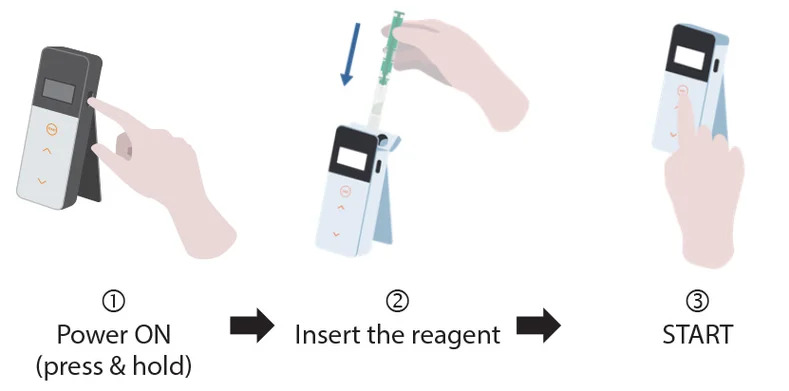

To create practical and reliable ATP hygiene test limits, the University of Wisconsin–Madison conducted a detailed study using the Kikkoman A3 ATP Test. Their approach demonstrates how data can define achievable hygiene standards that still drive improvement.

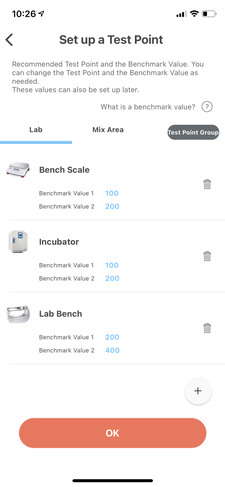

1. Selecting Test Points

Ten representative points were chosen for testing:

- 5 from CIP (Clean-in-Place) systems

- 5 from COP (Clean-out-of-Place) systems

Each point was tested both before and after cleaning to measure the true effect of sanitation.

2. Collecting Data

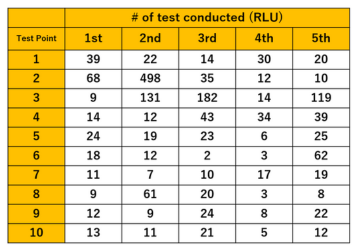

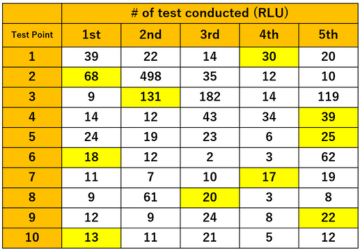

Each point was swabbed or tested five times to understand variation. For example, CIP points produced a range of readings that helped identify normal, clean performance versus residual contamination. The CIP test points yielded data such as:

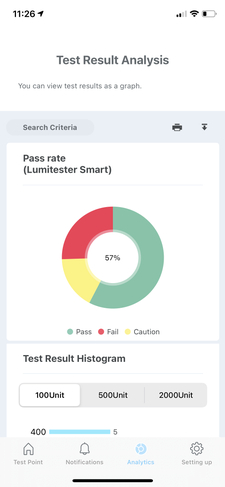

3. Setting the Pass Limit (≈80% Passing Rate)

To establish realistic pass limits, researchers used the second-highest value from each set of five measurements. This approach filters out extreme outliers while still representing a “worst realistic case.”

Example pass limits:

- Test Point 1 → 30 RLU

- Test Point 3 → 135 RLU

- Test Point 10 → 15 RLU

This method ensures that roughly 80% of post-cleaning results pass, strict enough to ensure hygiene, but practical enough to maintain motivation.

4. Confirming Validity

Once limits are set, they must be validated with real data. If post-cleaning results consistently meet those values, the limits are confirmed as effective. If pass rates are too high, standards can be tightened; if too low, limits may be adjusted to avoid discouraging staff.

5. Revalidation

Pass/fail limits are not permanent. They should be revalidated whenever detergents, cleaning tools, or suppliers change. These variables directly affect cleanliness outcomes, so regular review ensures continued reliability and compliance.

Key Takeaways

- Use data-driven limits rather than arbitrary thresholds.

- The second-highest value method balances practicality and rigor.

- Revalidate limits when cleaning conditions or processes change.

By following this evidence-based method, hygiene programs can establish limits that are both scientifically sound and achievable, enhancing food safety, audit readiness, and staff confidence.

Exportable Data and Reports for Regulatory Compliance

Exportable Data and Reports for Regulatory Compliance

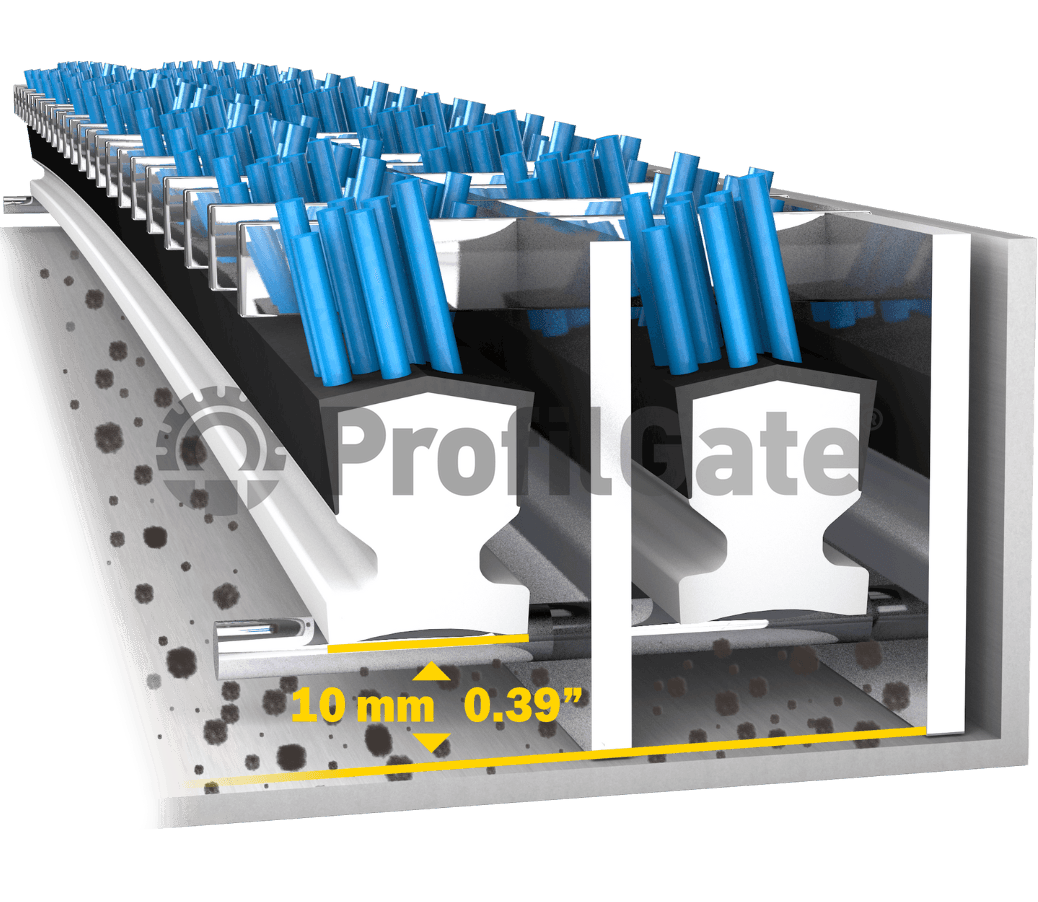

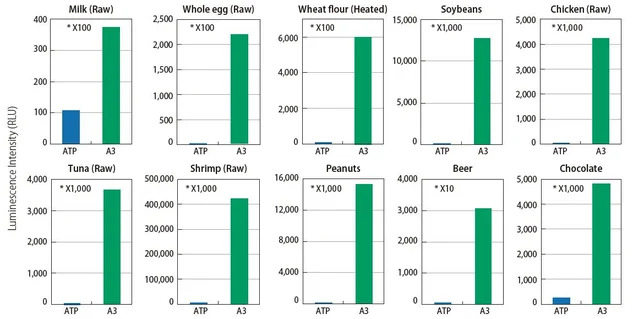

See how A3 technology finds what ATP technology can’t

See how A3 technology finds what ATP technology can’t